Spirulina Process

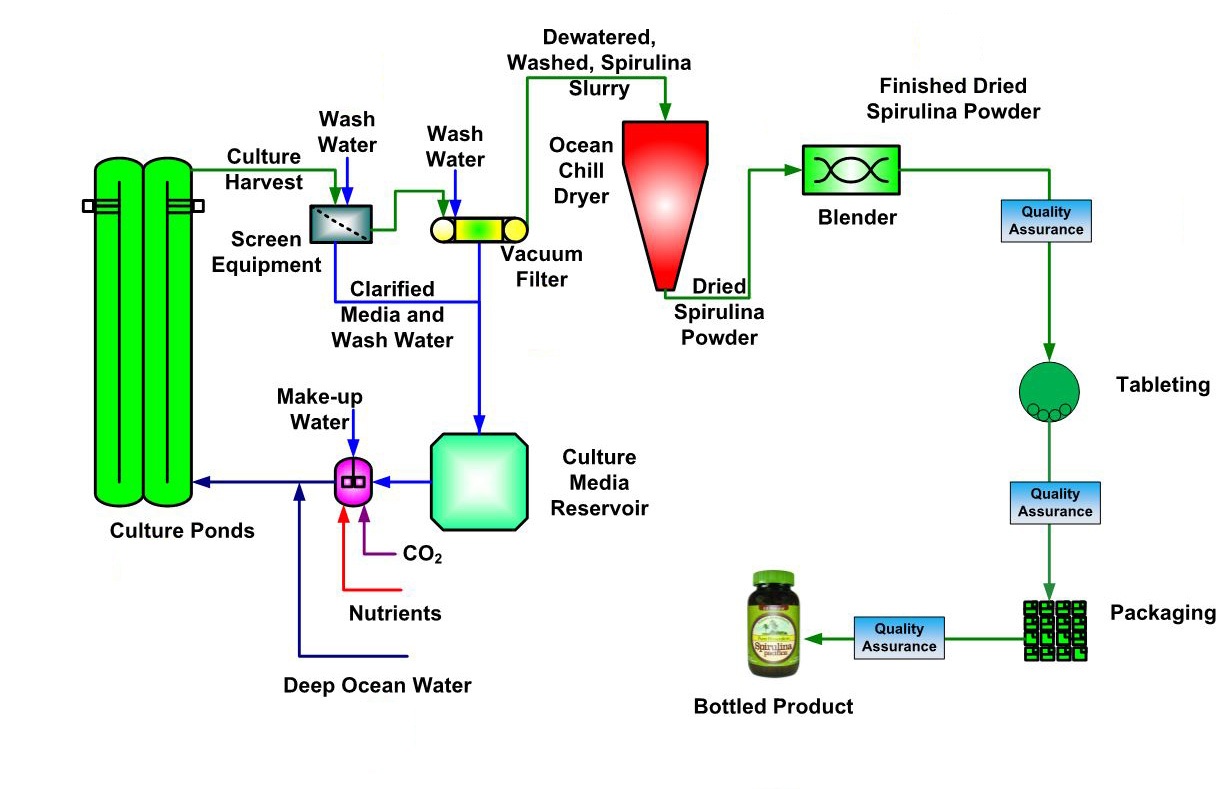

Hawaiian Spirulina is the only cultured microalgae grown with ultra pure deep ocean water as a source of minerals and trace elements. The deep ocean water is pumped up from a depth of 2000 feet, supplying magnesium, calcium, and every trace element. This unique resource is also used in our drying system (see ocean chill drying).

Hawaiian Spirulina thrives in shallow ponds adjacent to the Pacific Ocean. Gentle stirring by paddle wheels assures perfect exposure to the intense Hawaiian sun. The growing medium employs a mixture of fresh water and mineral-rich deep ocean water in a base of food-grade baking soda. This managed growing system assures a contamination-free, consistently superior nutritional profile.

We meticulously wash Hawaiian Spirulina over stainless steel screens. Using a pollution-free, 100% recycled process, we return all the pond water to the growing ponds for the next growing cycle.

Prior to drying, we rinse Hawaiian Spirulina three times. Numerous fresh water rinses give Hawaiian Spirulina a mild, salt-free taste.

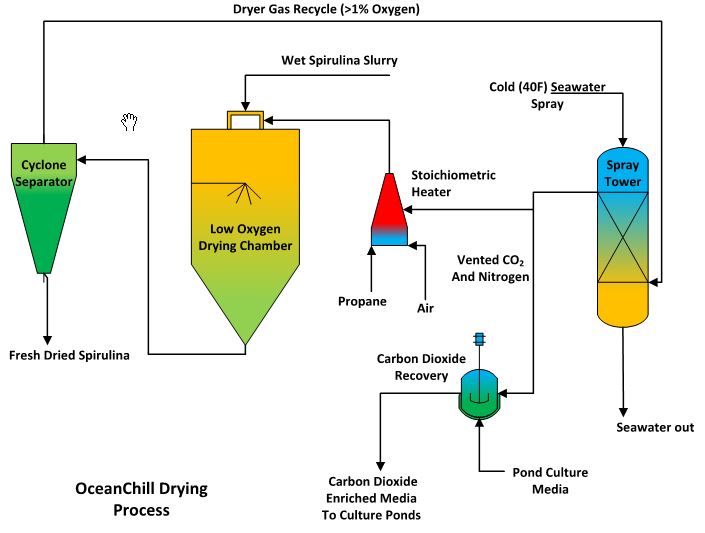

We developed Ocean Chill Drying especially to eliminate the oxidation of carotenes and fatty acids that occurs in standard dryers. The process employs a closed system which is kept at less than one percent oxygen by flushing with nitrogen and carbon dioxide. We have patented this process, which relies on very cold deep ocean water to provide dehumidification. This process is unique to Hawaiian Spirulina.

The dried powder is immediately protected from oxidation. Using a process we pioneered, oxygen absorbers are enclosed in heat-sealed, metal-lined drums. This method of packaging assures that our customers receive Spirulina that is essentially as fresh as the day it was harvested.

Tableting Spirulina provides challenges because of the fine, dusty particle size. Commercial tableters often solve this problem using a heat process called granulation which can degrade nutrients. We built an advanced tableting facility specifically for Spirulina, enabling us to make tablets with a cold compression technique.